No products in the cart.

Can I apply the rust converter on an already painted surface?

Yes, you can do this. However, if the underlying rust is not removed and the edges of the paint are not feathery, then it will not last as long. The product can only treat what it comes in contact with and if a layer of rust is on all sides, it will act as a ring around the paint, preventing any new material from penetrating.

If there is oxidation under the paint, eventually that paint will fail to adhere and it will take the rust converter with it.

Can I use a garden sprayer?

You can, but it will be harder to control the spray pattern and get a completely uniform coat. It might also slow drying time and decrease coverage area due to putting on a heavier coat. Watch that the nozzle does not clog, this is a high solids product that could cause issues with smaller droplet spray patterns.

Can I spray a coat of XionLab 2 & 1 and spraying one coat of enamel?

Yes…one coat, our rust converter should be ok.

After letting the XionLab Rust Converter dry, a dull white residue appeared on the surface. Is it normal?

What you are seeing is some residual salts from the phosphating process. This happens occasionally on very rusted and porous surfaces, it is a byproduct of the rust being converted. In most situations, this can be simply wiped off before applying a top coat. If you use a mild detergent to aid in this process, make sure to rinse thoroughly and let it fully dry before applying the top coat. If you are not applying a top coat, this residue will slough off on its own.

What is the recommended spray tip for an HPLV spray gun? What pressure setting is best?

Make sure that you follow the label directions and thin the product with no more than 20% water by volume and mix thoroughly.

When being used in any sprayer, it is imperative that the directions for the sprayer be followed closely. Straining the final ‘thinned’ mixture as you put it into any sprayer is recommended by any spray gun manufacturer. Typical pressure used for an HVLP gun is 15-25psi, depending on the tip and how thin you reduce the product.

The size of the strainer should be relative to the spray nozzle. If you have a 1.4 mil nozzle (ideal); for example, this means that any particle larger than 1.4 mil will clog the gun and adversely affect the performance. Disposable paint strainers are available almost anywhere paint is sold, this would be the preferred recommendation for any spray application.

There will always be some level of precipitate that exists, so do not be alarmed if the strainer catches some unincorporated solids.

Mix the 2 in 1 or shake it in a paint shaker first; then thin the fully mixed paint with up to 20% water. Mix the thinned paint and then pour it through your paint strainer, directly into the reservoir on the paint gun. This will yield the best coverage and performance.

Can you apply this product over BONDO?

It is not recommended to use it on anything else than mild steel, stamped plates, cast iron, brackets, and other automotive parts.

How long has this product been on the market?

Our Rust converter has been on the market for over ten years now and is used in many industries such as maritime, automobile, farming…

If need be, how is this product removed?

Once dried, sanding it will be the best way to remove it.

Is it more difficult to get smooth paint job?

It should not make it difficult; it also depends on how you apply the rust converter & primer, with a spray gun, brush, or roll.

What do I need to do to apply this product with a spray gun?

Applying the product with a spray gun is a very easy process. We recommend diluting the product 20% with water and running it through a strainer, fine enough to catch any particles that are larger than the openings in the tip. Only dilute what you are going to spray and discard any unused portion, just like any other coating. Clean the gun with simple water and a small brush. Follow the manufacturer’s recommendations for disassembly and cleaning of the spray gun.

Can I use your 2-1 rust converter on my new steel parts that are not rusty as a primer?

Yes, you can use this on bare ferrous metal. Many times there is still minor oxidation that this product will attack and protect. Be sure any oils, grease, or protective coatings are stripped from the bare metal before coating.

Can I use Xion Lab Rust Converter & Primer on vehicle parts such as rear end, crossmembers, brackets and other small parts?

Yes, our product is ideal for all mild steel, stamped plates, cast iron, brackets, and other automotive parts.

If I scrape all loose rust and then apply two coats, will it extend the life of the pan?

Our product will protect your pan from further oxidation and thus extending its useful life.

What is the minimum temperature that your rust converter can be applied?

We do not recommend using our rust converter under 50 degrees.

Will it be ok to pour concrete around the treated rebar?

Concrete is no problem.

I live in an area with temperatures goes below zero. Do I need to be concerned that my converter was exposed to below freezing temperatures?

Absolutely not. Our product expands and contracts with heat and freezing temperatures. This is one of the things that make it so effective, is the ability to maintain solid adhesion despite temperature swings.

Will your product adhere to a galvanized steel roof that is rusted?

This product should not be used on soft metals, such as galvanizing. It is a low pH product that will etch into soft metals. If the galvanization is gone and it is only steel, our product will work well.

My one concern is that your product dries to a red color and I am looking for a final color of black. Is it possible to add a dye pack or pigment to your product to achieve this?

The product has not been tested with added dyes, we do not recommend this. It is preferred that you apply a topcoat in the color of your choosing.

Would the 2 in 1 rust converter be usable on a steel hull boat. Will an epoxy primer and paint adhere to the 2 in 1?

Yes, the product has been used in many maritime applications with great success. It shows great adhesion when used with an epoxy primer.

After applying the base coat of the rust converter, how long can/should I wait to topcoat?

The product should be fully cured, before applying another coat. Relative humidity, temperature, airflow, and sun exposure all affect curing; however, we recommend a baseline of 24-48 hours to cure completely.

If I choose to top coat with another product, how long can I wait before applying?

The product should be fully cured, before applying another coat. Relative humidity, temperature, airflow, and sun exposure all affect curing; however, we recommend a baseline of 24-48 hours to cure completely.

is this a moisture cured product?

No, it is not, it is a water-based product that cures through a typical evaporation process.

Is it OK to thin with water does that mean I can spray and not worry about any minor moisture in air line?

Yes, as long as there are no other contaminants such as oil or silicone. The presence of moisture in the line might affect the appearance of the final dried product as it could yield an inconsistent spray pattern.

What is the life of opened & unopened can?

It is best to use it once it has been opened, but if you cannot…you should try to use the remainder within 3 months. It is imperative that you seal the container well to avoid the product drying out. Any unopened container should be used within 12 months and protected from freezing or superheating while in storage. Once the product has been applied and cured, freezing and heating are no longer an issue. This product is >50% solids, so it will settle over time, make sure to mix or shake it thoroughly before any use.

Is unused portion best poured off into full smaller containers?

No, we do not recommend transferring leftovers into a smaller container. The instructions and product information label should always be on the container the product is housed.

If brushed or rolled can it be worked or are you supposed to avoid a lot of movement once down?

It is best to put it down and leave it alone until it cures.

Would you recommend this product for these applications to prevent rusting?

Yes, this product would work to protect almost any ferrous metal product.

Can I use it on a roof vent that's aluminum and on galvanized steel?

No, this product is not for use on aluminum or galvanized steel.

What kind of your product is suitable for industrial furnace applications?

This product has been successfully tested for expansion and contraction up to 300F and showed no issues with adhesion. The product might discolor at the higher range, but it did not affect the performance.

Do you have experience with your rust converter in industrial furnaces?

This product has been successfully tested for expansion and contraction up to 300F and showed no issues with adhesion. The product might discolor at the higher range, but it did not affect the performance.

How long does it take before full drying and/or coating by next application?

Typically 48 hours depending on relative humidity, temperature, airflow, and sun exposure.

What is the maximum permanent (operating) temperature of exposure allowed on the formed layer as a result of using your product?

Our product has been tested up to 300F.

At a constant temperature of about 212 ° F, how many years will the formed layer last?

It is impossible to assess that with limited information. There are many other factors that come into play, but our product has been tested up to 300F.

After applying the rust converter, can metal elements be welded onto the formed layer without removing the layer?

Our product is not a weld-through primer, you will need to expose the bare metal to fuse it properly.

What is the approximate quantity of rust converter needed to apply on an area of about 11,840 sq.ft, and how much will it cost?

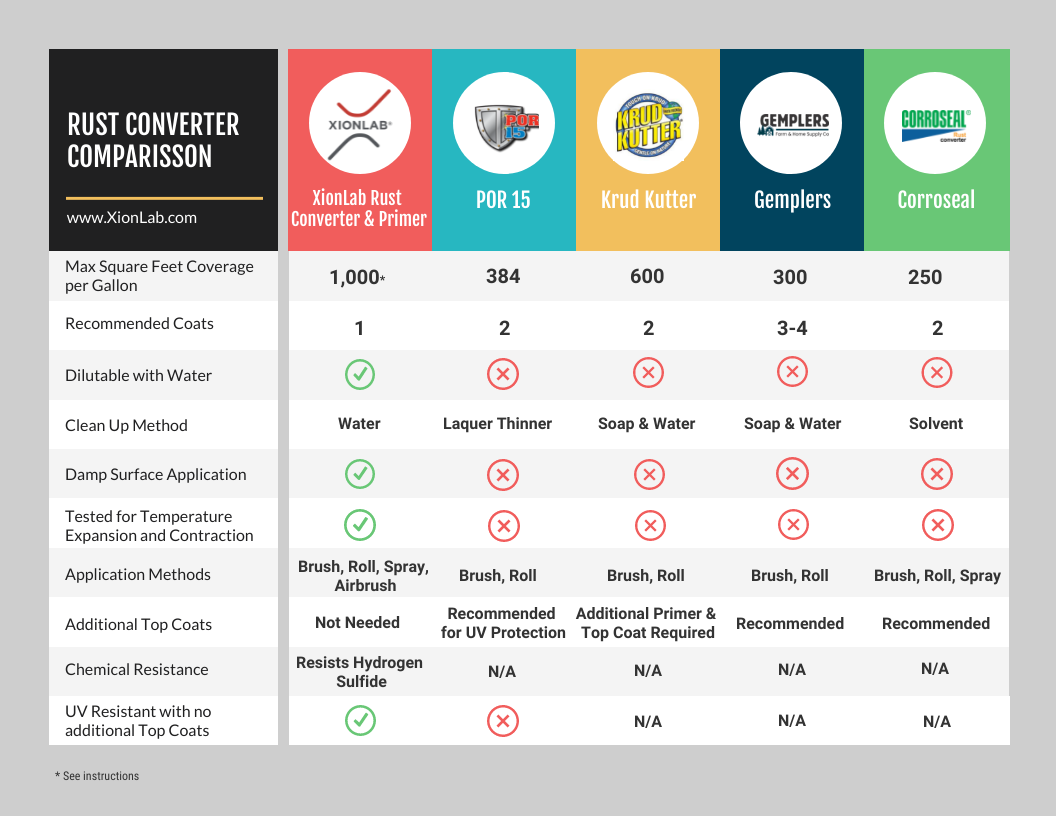

At 1.0mil dry thickness, you can cover about 1,000 sq feet. Any channels or brakes in the metal tend to collect additional material and affect the coverage. If your surface is perfectly flat and you are using a sprayer, we would recommend approximately 12 gallons plus a 10-15% overage, to cover any product lost in transfer, drift, or pooling.

Will the Xion Lab Rust Converter and Primer works in salt water?

It has been used in both saltwater applications as well as brackish water and performed well.

Raki eNovo –

good

Raki eNovo –

nice